Ultimate Guide to Dyeing Three-Component Fibers: Unlocking Complex Fabric Color Effects and Strategic Timing Choices

Amidst the wave of innovation in textile industry, three-component fiber fabrics have emerged as representatives of high-end products due to their exceptional performance and unique style. However, these fabrics encounter technical challenges during the dyeing process—such as diverse fiber combinations, complex blending ratios, variations in dyeing properties and unavoidable cross-staining issues—make dyeing process exceptionally intricate and difficult to control in terms of color result. This article will analyze the core challenges of dyeing three-component fiber and explore how to transform these challenges into competitive advantages through precise selection of dyeing stage and textile dyeing machine.

Why Is Dyeing Three-Component Fiber So Challenging?

Dyeing of three-component fiber textile is significantly more complex than traditional two-component fabric, primarily due to three core challenges as below:

Chemical compatibility conflict: Three types of fiber often require three different classes of dyes (e.g., disperse, cationic and acid dyes). These dyes may interact with one another in the dye bath, leading to reduced color purity.

Difficulty in controlling cross-staining: Staining of dyes on non-target fiber can blur color boundaries, making it hard to achieve clear solid or contrast color effect.

Conflicting process condition: Different fiber has optimal dyeing temperature, pH level and duration. Finding balance among these is like walking tightrope.

Analysis of the Four Major Dyeing Effects

Solid Color Effect – Different fibers exhibit similar hue, lightness and chroma

Differences in fiber gloss and light transmittance can significantly affect the final result.

The most challenging part of solid dyeing is for two-component textiles containing polyester dyed with disperse dyes and other disperse-dyeable fibers (such as acetate or other synthetic fibers). Though adjusting the dyeing temperature and adding dyeing carriers can modify the uptake of disperse dyes on both fiber, these adjustments have certain limitations.

- For polyester/nylon or polyester/acrylic blended interwoven product, acid or cationic dyestuff can be used to adjust color of nylon or acrylic fiber to match that of polyester. In the case of solid dyeing for acetate/polyester interwoven fabrics, achieving deep shades is particularly difficult. Under harsh dyeing conditions, acetate fibers are prone to damage, making deep-shade solid dyeing via one-bath method practically unfeasible.

- For blends or interwoven fabrics containing acid-dyeable fibers (such as nylon or acrylic) and cationic-dyeable fibers (such as nylon, polyester, or acrylic), solid colors can be achieved relatively easily through color matching. This is because cross-staining between the two dye/fiber systems is minimal, resulting in good dyeing reproducibility.

Reserve Effect – One fiber is dyed while the other remains white.

It is relatively easy to achieve this effect when synthetic fibers serve as the reserved component. For example, in blended or interwoven fabrics such as wool/polyester, silk/polyester, wool/acetate, or viscose/polypropylene, polyester, polypropylene, and acetate fibers generally do not pick up color when wool, silk, or viscose fibers are dyed.

Reserving protein fibers is extremely difficult. For instance, if wool is intended to remain white while acetate and polyester fibers are dyed with disperse dyes, the wool tends to stain heavily, and the disperse dye stains on wool are very difficult to remove.

In protein fiber/regenerated cellulose fiber textiles, many acid dyes do not dye or stain regenerated cellulose fibers under acidic conditions, making it relatively easy to reserve regenerated cellulose fibers.

How can staining on reserved fibers be effectively minimized in two-component textiles with reserve effect?

1.Select dyes that have high affinity for the fiber to be dyed, little to no affinity for the reserved fiber, and whose stains are easy to wash off.

2.Optimize dyeing conditions (e.g., temperature, pH) to maximize dye exhaustion onto the target fiber and reduce staining on the reserved fiber.

3.Use colorless additives (reserving agents) that selectively adsorb onto the reserved fiber. These agents should share the same adsorption mechanism as the staining dyes on the reserved fiber.

4.After dyeing, remove stains from the reserved fiber with cleaning agents or use reducing agents to destroy the chromophores of the staining dyes.

Tone-on-Tone Effect – Two fibers are dyed in similar hues but with different depth of color

This effect is easiest to achieve with fiber combinations that have similar dyeing properties, as variations in crystallinity, orientation, cross-sectional and surface structure, gloss, etc., within the same fiber series naturally result in differences in apparent color depth.

Examples include:

1. Blended or interwoven cellulose fiber products (such as linen/cotton, cotton/Lyocell, linen/Lyocell, viscose/Lyocell, etc.) dyed with direct or reactive dyes.

2. Fabrics like acetate/polyester, conventional polyester/deep-dyeable polyester, polyester/polylactic acid fiber and polyester/PTT fiber dyed with disperse dyes.

3. Textiles such as nylon/wool, wool/mohair, wool/silk, wool/soybean fiber, silk/soybean fiber, and light-dye/deep-dye nylon dyed with acid dyes.

For fiber combinations with different dyeing properties, tone-on-tone effect can also be achieved by using two types of dyestff to color two fiber separately, followed by careful color matching.

Tone-on-tone effect is essentially an intermediate outcome between solid color and reserve effect. It is generally considered optimal when the apparent color depth of one fiber is about one-third to one-half that of the other fiber.

Contrast Color Effect – This effect aims for either strong color contrasts or subtle color coordination

It is essential to avoid cross-staining of dyes, as staining not only compromises the vibrancy and contrast of the colors but also increases the difficulty of color matching and reduces the wash and rub fastness of the dyed product.

Fiber combination selection is crucial for achieving this effect. Two-component fiber textiles often utilize fiber combinations with significantly different dyeing properties. Examples include synthetic fibers paired with protein or cellulose fibers, acid-dyeable synthetic fibers combined with cationic-dyeable synthetic fibers (e.g., nylon/acrylic), and protein fibers combined with cellulose fibers.

Selection of Dyeing Methods: Strategic Considerations from One-Bath One-Step to Two-Bath Processes

The choice of dyeing method for multi-component fibers directly impacts the final outcome and production costs.

Four Main Dyeing Processes

One-Bath One-Step Process: A single dye is used to color multiple fibers simultaneously in one bath. It is suitable for fiber combinations with similar dyeing properties.

One-Bath One-Step Dual-Dye Process: Two dyes are applied in the same bath to dye different fibers separately. This method requires good compatibility between the dyes.

One-Bath Two-Step Process: Dyeing is conducted in a single bath but in two distinct stages, accommodating different dyeing condition requirements.

Two-Bath Process: Fibers are dyed separately in two baths. This is the most flexible method but also the most costly, making it suitable for complex fiber combinations.

Key Considerations for Process Selection

- Adaptability of fibers to dyeing temperature and pH.

- Compatibility between dyes and the degree of cross-staining.

- Color requirements and fastness standards for the final product.

- Balance between production cost and efficiency.

Textile Dyeing Equipment: Key Support for Achieving Ideal Dyeing of Multi-Component Fibers

In dyeing process of multi-component fibers, advanced dyeing equipment serves not only as the medium for implementing the process but also as core element ensuring dyeing quality and realizing the intended design effects.

Direct Correlation Between Equipment Selection and Dyeing Results

The appropriate selection of dyeing equipment directly influences the fabric's:

- Hand feel retention and style presentation

- Color uniformity and reproducibility

- Control of fiber damage

- Efficiency in energy and chemical consumption

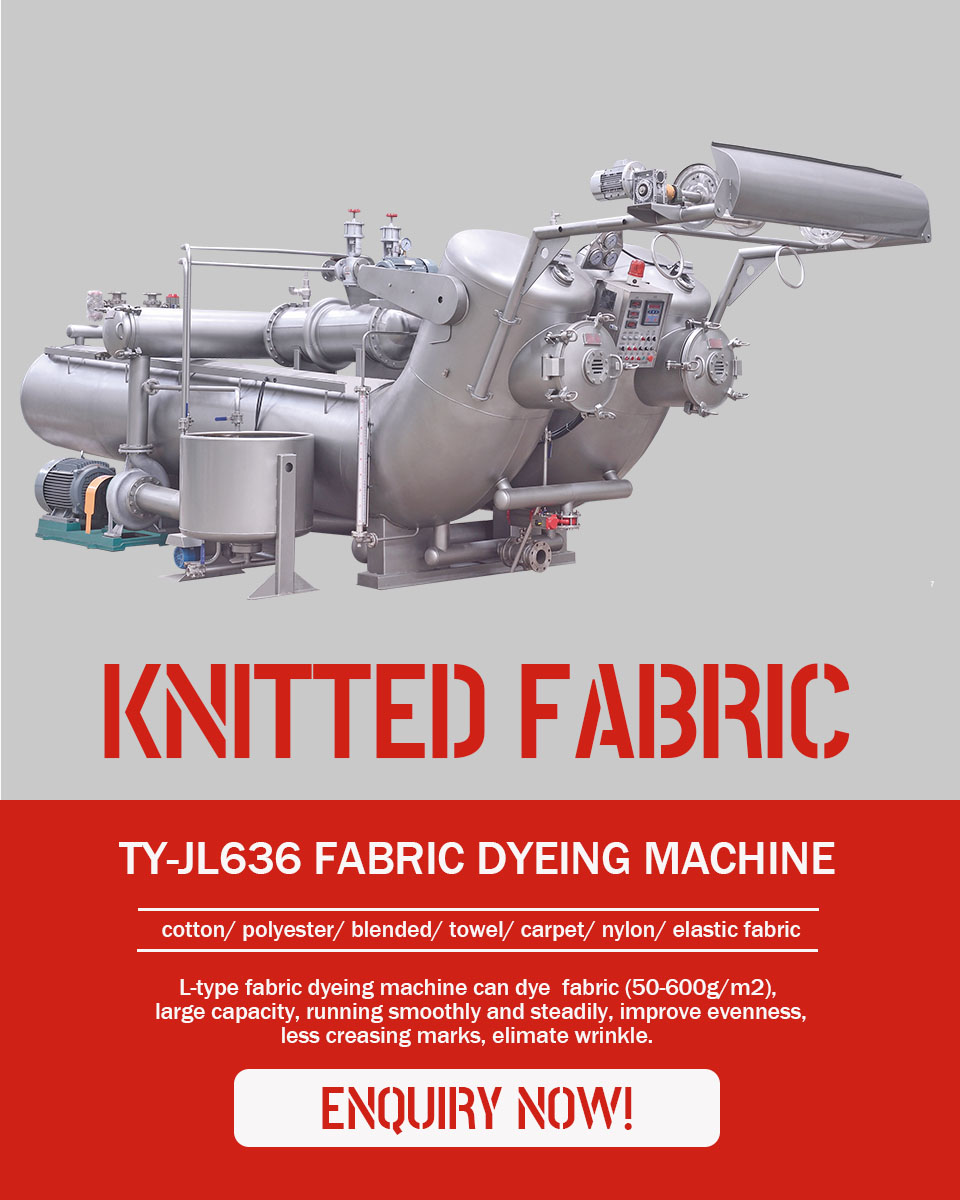

Batch Dyeing Machine is More Prevalent for Multi-Component Fiber Textiles

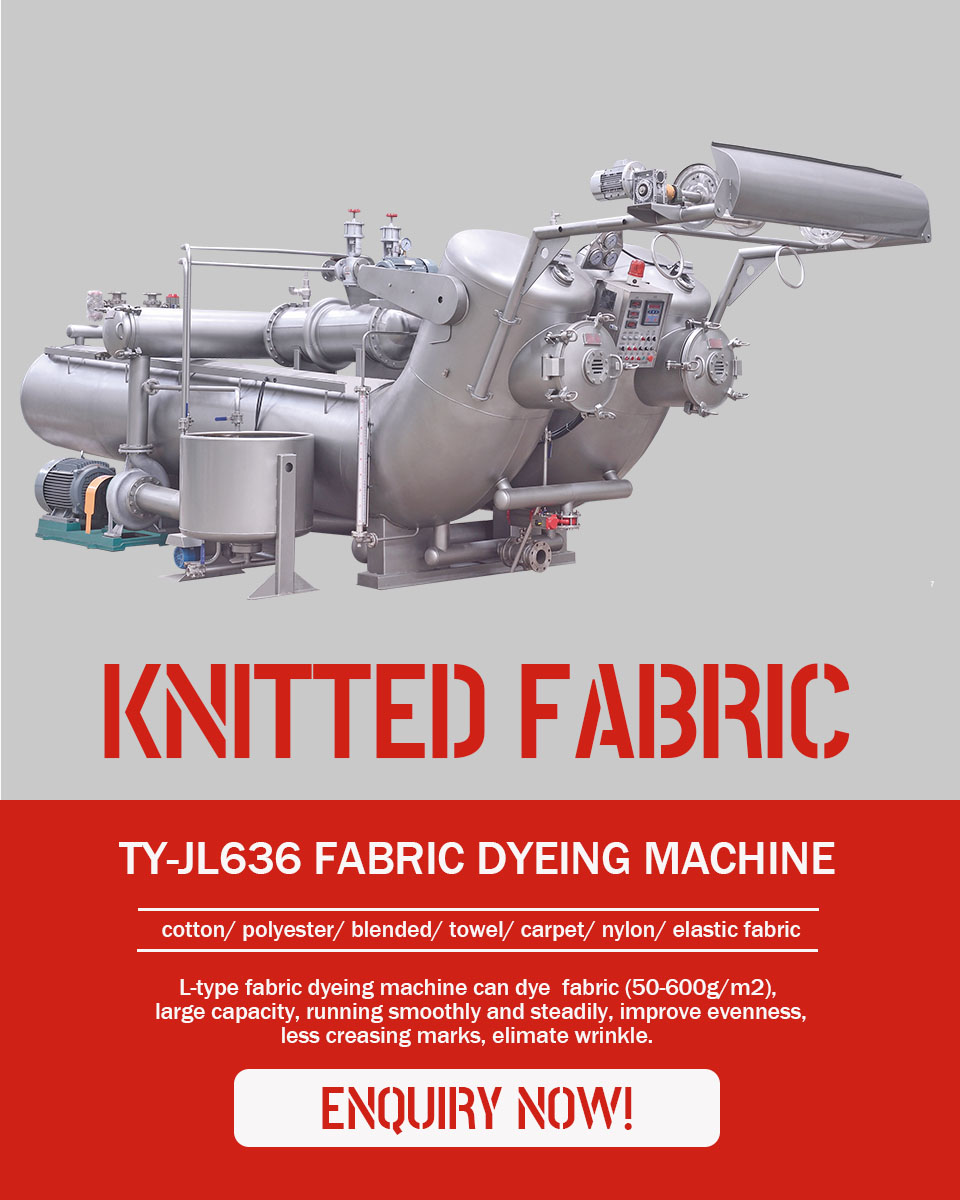

- Woven fabrics are commonly dyed using open-width jig dyeing machines, beam dyeing machines, and jet or overflow dyeing machines.

- Knitted fabrics are typically dyed using winch dyeing machines and jet or overflow dyeing machines, with hthp dyeing equipment used for varieties containing polyester.

- Blended yarns are often dyed using hank dyeing machines and package dyeing machines.

Trend in Specialized Dyeing Equipment for Multi-Component Fiber

To meet the specific demands of multi-component fibers, modern dyeing equipment is developing in the following directions:

- Precise Temperature Control Systems:Enable optimal dyeing temperature control for different fibers.

- Intelligent pH Management: Automatically adjusts the acidity/alkalinity of the dye bath to suit different dye requirements.

- Low Liquor Ratio Technology:Reduces chemical consumption and lowers the risk of cross-staining.

- Flexible Dyeing Programs:Allow programmable multi-stage processes to adapt to complex dyeing sequences.

Dyeing can be carried out at various stages of multi-component fiber fabric manufacturing. Based on the physical form of the material being dyed, there are typically four dyeing methods:

1. Loose Fiber or Top Dyeing(fiber dyeing machine):

The final fabric can achieve heather or solid color effects. This method offers the best dye penetration and requires high color fastness. Color difference in blended products is minimal. However, it has the highest cost, involves numerous processing steps before the final product is ready and utilizes fiber blending after dyeing, resulting in significant fiber waste.

Typical Applications:Yarn for wool knits, tweeds, thin twill for outerwear, medium to heavy weight fancy suitings; used for dyeing raw materials (for solid or contrast colors) in multi-component (three or more) fiber-blended textiles.

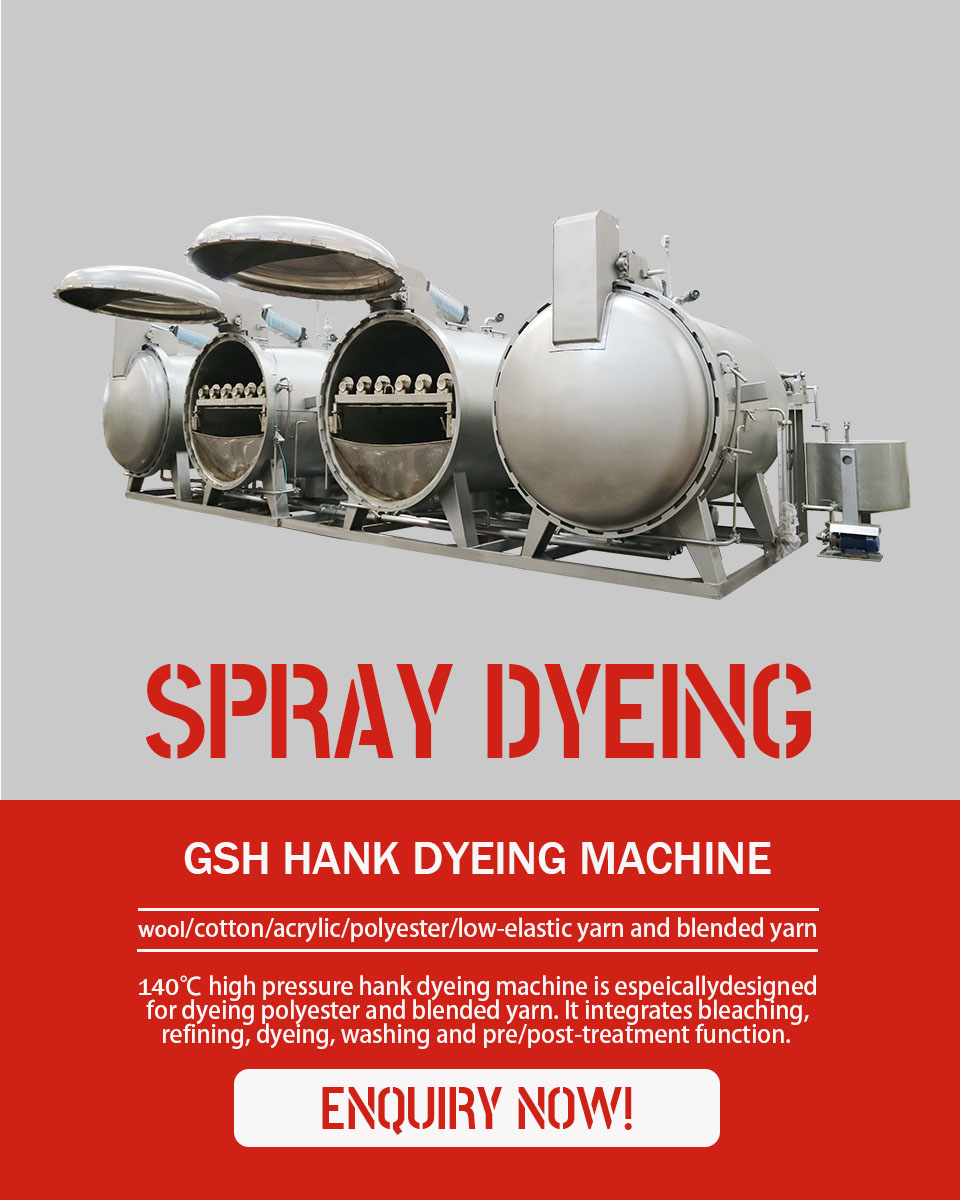

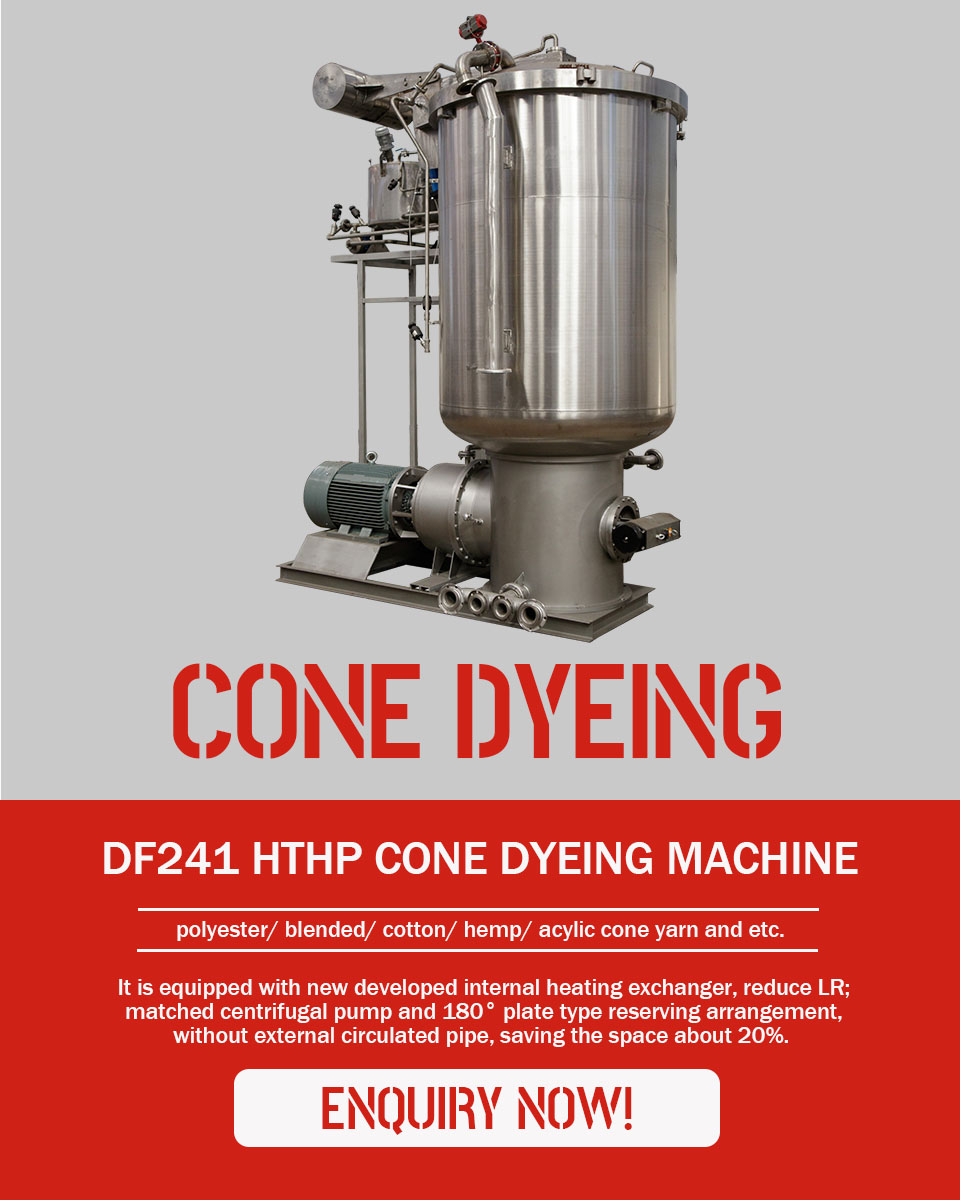

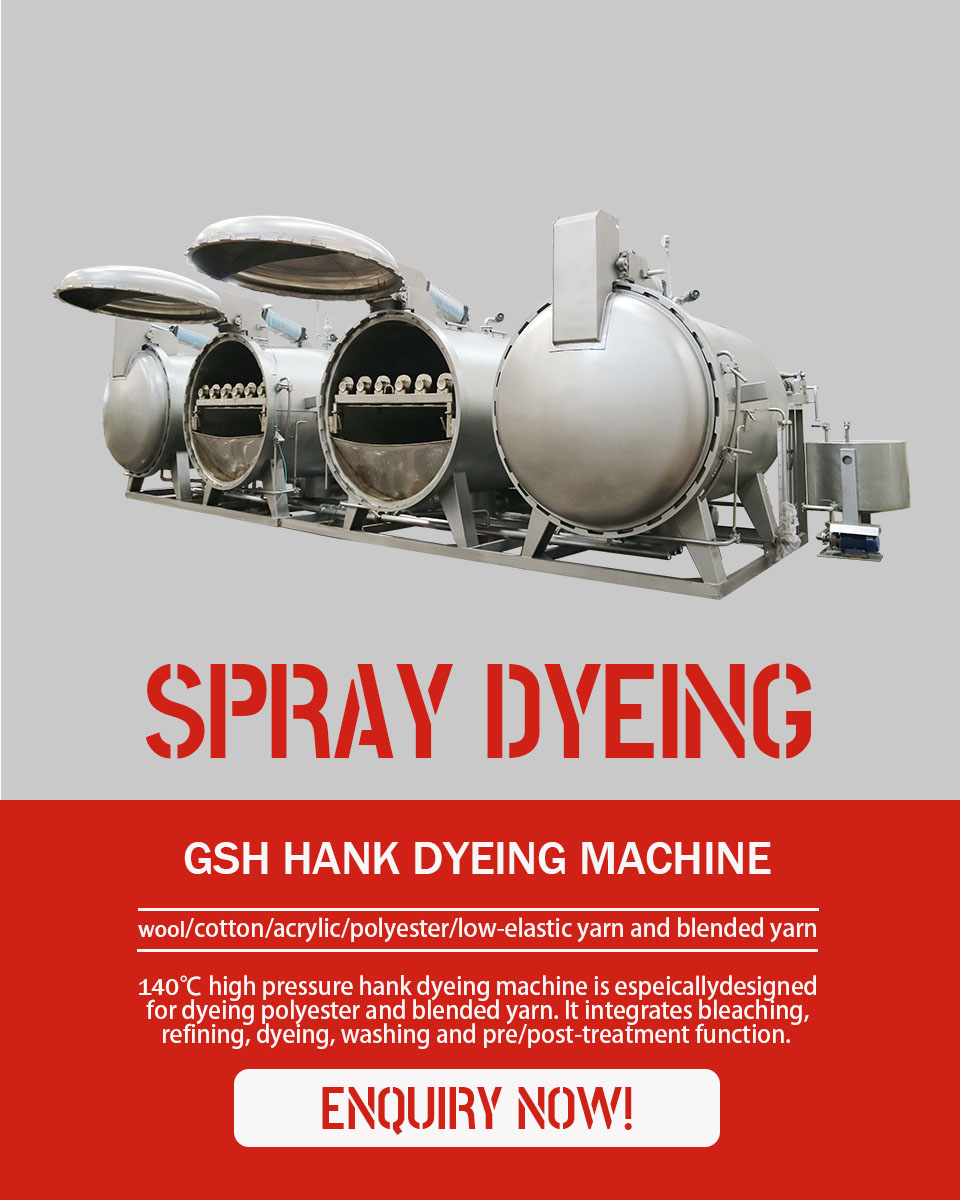

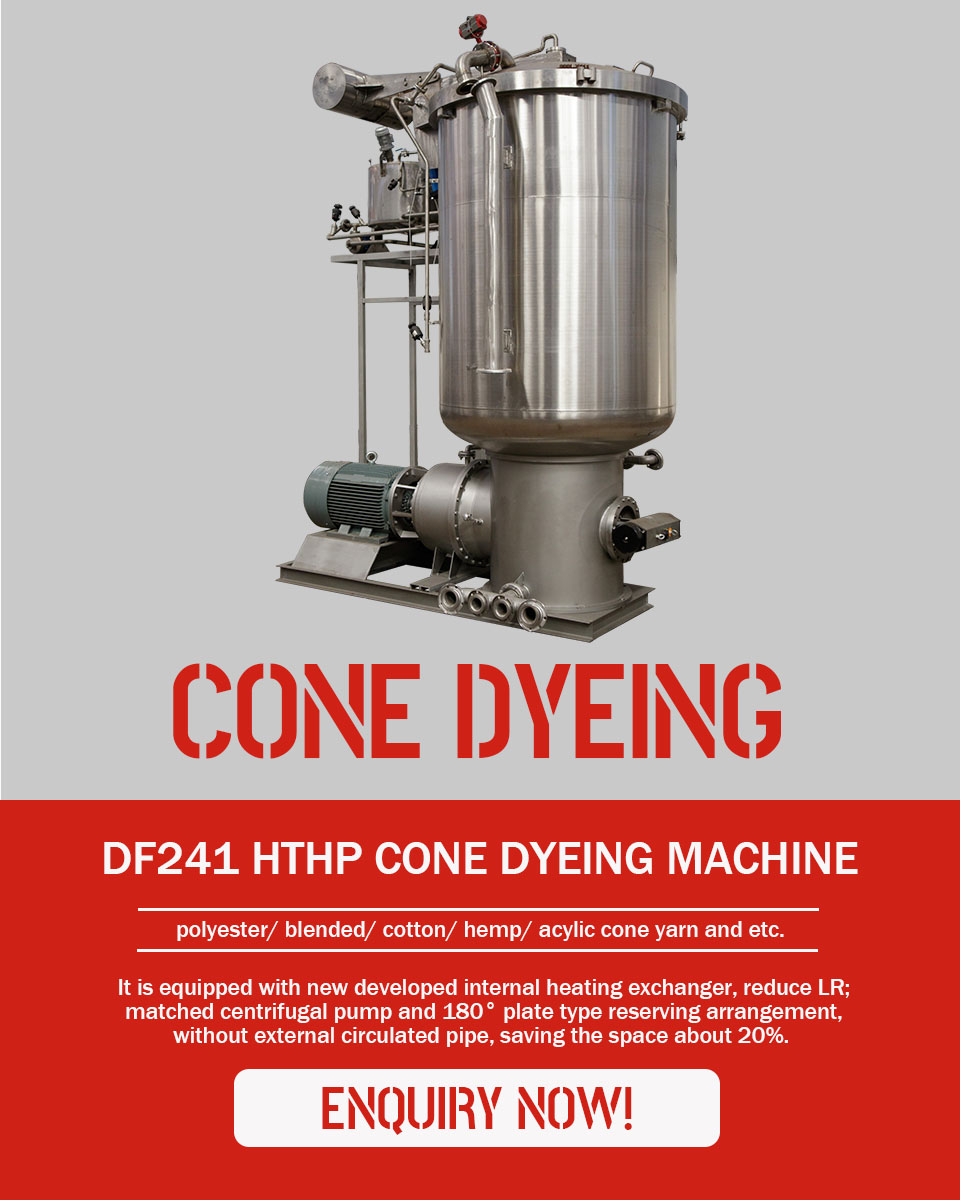

2. Yarn Dyeing (cone dyeing machine or hank dyeing machine):

Used for producing yarn for striped, checkered and other multi-color style fabrics. The cost is moderate, the process is relatively lengthy and material loss is considerable.

Typical Applications:Knitting blended yarns, striped/checked fabrics, brocades, jacquard fabrics, blended yarn-dyed textiles.

3. Fabric Dyeing (overflow dyeing machine, jet dyeing machine, fabric dyeing machine)

This method has low cost and it is suitable for various knits and woven fabric, allowing for quick color updates in apparel fabric. It is mainly limited to achieving solid color or reserve (white) effect. Dyeing fabric with three or more fiber type is challenging.

Typical Applications:Various plain and crepe fabrics, woolen materials, lightweight wool fabrics, corduroy, satin weaves and other fabric—primarily those made from pure or two-component fibers.

4. Garment Dyeing(garment dyeing machine):

Best meets the demand for rapid color updates in apparel, with no waste of pre-dyed yarn or fabric. It is only suitable for garment with simple structure.

Typical Applications: Socks, tights, knitted sweaters, T-shirts, pants and shirts with loose structures, and vintage/stone-washed denim products.

Wuxi Shin Tong Yunn: Expert in Multi-Component Fiber Dyeing Solutions

As one of the professional yarn and fabric dyeing machine manufacturer in China, Wuxi Shin Tong Yunn has deep understanding of complexities and technical requirements involved in multi-component fiber dyeing processes. Our textile dyeing machine design and technological innovations are consistently centered around addressing the practical challenges faced by textile dyeing industry.

How Our Dyeing Equipment Tackles Multi-Component Dyeing Challenges:

1. HTHP Dyeing Machine Series

- Precise temperature control range (up to 140°C) meets the needs of polyester and other synthetic fibers.

- Gentle heating and cooling curves protect sensitive fibers like acetate.

- Suitable for combinations such as polyester/cellulose fibers and polyester/nylon.

2. Multi-Functional Jet Overflow Dyeing Machine

- Gentle mechanical action preserves fiber structural integrity.

- Suitable for knitted fabrics and sensitive woven fabrics.

- Particularly ideal for delicate blends like wool/synthetic fibers.

3. Intelligent Dyeing Control System

- Multi-program storage allows for quick switching between processes for different fiber blends.

- Real-time monitoring and adjustment of dyeing parameters.

- Ensures dyeing reproducibility and consistent quality.

Successful Application Cases: Practical Three-Component Fiber Dyeing

We have collaborated with numerous textile enterprises to successfully achieve high-quality dyeing for various complex fiber blends:

Case 1: Polyester/Cotton/Spandex Elastic Fabric

Utilized our high-temperature high-pressure dyeing machine.

Employed a one-bath two-step method with disperse/reactive dyes.

Achieved excellent solid color effect while maintaining elasticity.

Case 2: Wool/Polyester/Viscose High-End Suiting Fabric

Applied gentle overflow dyeing technology.

Implemented multi-stage temperature and pH control.

Achieved rich colors on wool and precise reserve effects on synthetic fibers.

Case 3: Nylon/Acrylic/Polyester Sportswear Fabric

Precise temperature control ensured optimal dye uptake for different dye types.

Special washing procedures minimized cross-staining.

Achieved vivid and durable contrast color effects.

Advancing Multi-Component Dyeing through Intelligence and Sustainability

With the accelerated innovation in textile materials, three-component and even multi-component fiber textiles will become mainstream in the market. Dyeing technology must evolve accordingly, with equipment innovation serving as the core driver of this progress.

Wuxi Shin Tong Yunn Machinery Technology Co., Ltd remains committed to:

- Developing more precise dye delivery and distribution systems.

- Integrating artificial intelligence to optimize dyeing processes.

- Advancing green technologies that reduce water, energy, and chemical consumption.

- Creating specialized dyeing solutions adapted to new fiber materials.

Dyeing multi-component fiber textiles is complex process that integrates materials science, color chemistry and precision engineering. The key to success lies in profound understanding of the interplay between fiber characteristics, dye behavior and dyeing machine capabilities. As professional partner in the field of dyeing equipment, Wuxi Shin Tong Yunn will continue to provide innovative solutions, helping textile enterprises overcome the challenges of multi-component fiber dyeing and achieve exceptional unity between color design & product quality.