Glass is one of the most common perfume bottle materials. It is loved for its high transparency, beautiful lines and good plasticity. The production cost of glass bottles is higher, but at the same time, they are more elegant. Its good sealing performance can well protect the fragrance of perfume from loss. However, glass materials are relatively brittle and can easily break or be damaged if accidentally touched.

2、 Plastic perfume bottle

The advantage of plastic bottle is that it is light and resistant to falling, which is more convenient to carry than glass perfume bottle. Plastic perfume bottles are more diversified in color and shape, and have better plasticity. However, plastic may cause damage to some perfume ingredients, and plastic materials are more likely to be oxidized, and the storage time is relatively short.

3、 Metal perfume bottle

Metal bottles pursue a luxurious, noble, and stable style, which is more exquisite and has a better texture compared to other materials. The treatment of metal perfume bottle material has more treatment for the surface, so as to maintain the high-end appearance level and make the metal material not easy to oxidize and rust. But its advantages also have certain disadvantages, such as being relatively heavy, difficult to carry, and high cost.

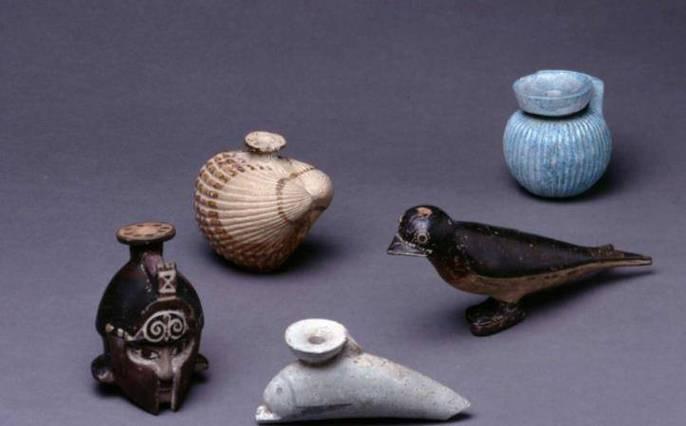

4、 Other perfume bottle materials

In addition to the above-mentioned common perfume bottle materials, there are also some special materials, such as ceramics and crystals. The ceramic perfume bottle reveals a simple, cultural and thick flavor, and is often used for elegant wedding perfume. The crystal material is full of beauty like jewel inlay, and is often used for high-end customized perfume.

To sum up, the materials of perfume bottles have their own advantages and disadvantages, and different materials should be selected for different functions and applications.