Angling is an activity that demands prolonged focus and endurance, with the fishing rod grip tape serving as a critical component connecting the angler to their equipment. Its design, material, and application directly influence the angling experience. From grip comfort to fish-control efficiency, the role of grip tape extends far beyond mere "anti-slip" functionality. This article explores, through scientific principles and practical experience, how grip tape reduces arm strain, enhances fish-control precision, and becomes an indispensable "invisible assistant" in angling.

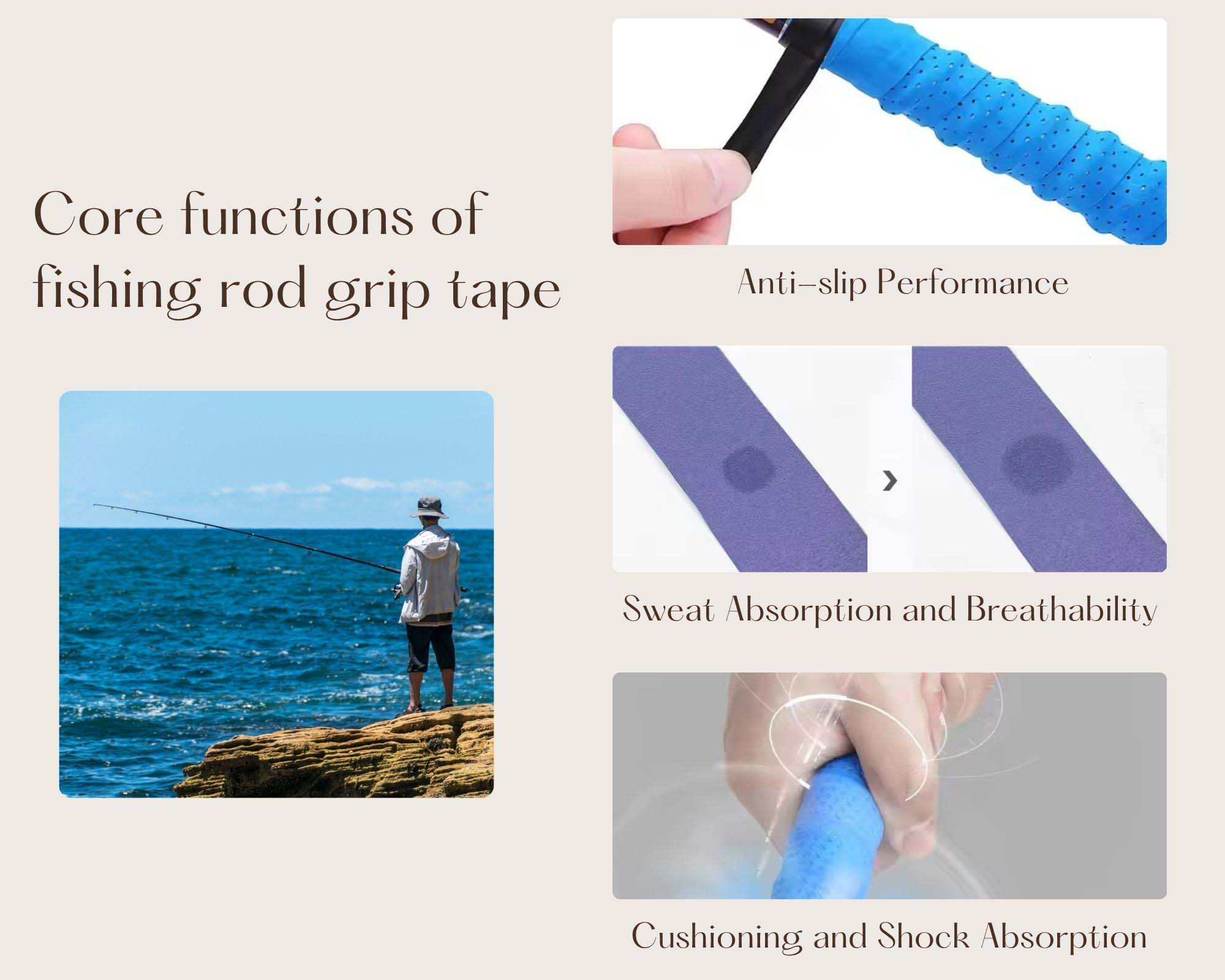

I. Core Functions of Fishing Rod Grip Tape

1. Anti-slip Performance: The Foundation of Safety and Precision.

During angling, the stability of the rod grip directly impacts fishing success. Grip tape designs featuring keel textures or matte finishes significantly increase friction between the palm and the rod, preventing slippage caused by sweat, rain, or sudden force from a struggling fish. In battles with large fish, inadequate anti-slip properties may lead to rod dislodgment or operational errors, whereas high-quality grip tape ensures stable control even during intense confrontations.

2. Sweat Absorption and Breathability: Reducing Hand Slickness and Stickiness.

Holding the rod for a long time can cause sweating, and traditional bare rods or low-quality grip tapes can become slippery due to sweat accumulation, exacerbating fatigue. Our KEET grip tapes primarily use sweat-absorbing materials like EVA, paired with breathable hole designs, to rapidly wick moisture and maintain dryness. This reduces the need for frequent grip adjustments due to hand slickness, thereby lowering muscle strain.

3. Cushioning and Shock Absorption: Keep the Fishing Rod Stability.

When a fish is hooked, the rod vibrates at high frequencies due to the fish's struggles. Without adequate cushioning, these vibrations transmit directly to the palm and arm, causing muscle soreness or even numbness. Premium grip tapes absorb part of the shock energy, reducing pressure on hand nerves—particularly beneficial for extended angling sessions or targeting large fish species.

II. Benefits of Fishing Rod Grip Tape

1. Enhanced Fish-Control Precision: Minimizing Power Loss.

If grip tape is too thin or excessively rigid, greater force is required to maintain stability during gripping, resulting in stiff movements and delayed reactions. Grip tapes with moderate elasticity and ergonomic designs reduce power loss, enabling anglers to execute delicate angling maneuvers more effortlessly.

2. Fatigue Reduction: Extending Efficient Angling Time.

Fatigue is the "silent killer" of angling efficiency. Grip tapes distribute pressure and reduce muscle tension, allowing anglers to stay focused longer. For example, tapes conforming to the natural curve of the palm effectively alleviate localized pressure, further minimizing grip fatigue.

III. Selection and Application Tips for Grip Tape

1. Wrapping Techniques: Details Define the Experience.

· Starting Point Fixation: Wrap from the bottom of the rod handle upward, ensuring 2–3 mm of overlap at the ends to prevent loosening at the interface.

· Tension Control: Maintain moderate tightness during wrapping to avoid wrinkles from being too loose or reduced elasticity from being too tight.

· Finishing Touches: Secure the end with specialized tape or heat-shrink tubing to prevent unraveling.

2. Regular Replacement and Maintenance

Grip tapes degrade and age over time, losing anti-slip and shock-absorbing properties. We recommend quarterly inspections, replace immediately if fraying, cracking, or reduced tackiness occurs. Additionally, wipe the grip tape surface with a damp cloth after each use to prolong its lifespan.

Angling is not merely a contest between man and fish but a dialogue with nature. Though small, grip tape embodies a pursuit of meticulous detail, enabling anglers to remain composed during battles with giants, relaxed while awaiting bites, and immersed in scenic beauty. The choice and use of grip tape fundamentally reflect an angler's deep understanding of their own needs. From anti-slip to comfort, from fish control to fatigue reduction, premium grip tapes elevate every detail of angling, ensuring a superior experience.